Procurement teams responsible for supply chains in 2025 face a wide range of risks, from financial instability and quality issues to ethical concerns and geopolitical disruptions. A strong supplier risk assessment process is essential to identifying these risks early, managing them proactively and protecting the organisation from costly repercussions.

Rather than treating risk assessment as a one-off task during supplier onboarding, the most effective procurement functions embed it throughout the supplier lifecycle. This ensures that risk data is accurate, up-to-date and actionable.

In this article, we’ll explore what supplier risk assessment involves, why it’s critical for procurement success, the challenges teams face, best practices to strengthen your process and how tools like Atamis can streamline risk monitoring and decision-making.

What is a supplier risk assessment process?

A supplier risk assessment process is a structured method for identifying, evaluating and monitoring potential risks associated with suppliers. The aim is to ensure that suppliers meet your organisation’s standards, comply with legal and regulatory requirements, and can consistently deliver on agreed terms.

Risks assessed typically fall into several categories:

- Financial risk: The supplier’s stability and ability to remain solvent.

- Operational risk: Their capacity, systems, and processes to deliver goods or services on time and to the right quality.

- Compliance risk: Adherence to industry standards, legal obligations, and internal policies.

- Ethical and sustainability risk: Labour practices, environmental impact, and supply chain transparency.

- Geopolitical risk: Exposure to political instability, trade restrictions, or sanctions in the supplier’s operating regions.

A robust process evaluates these risks both at onboarding and on an ongoing basis, helping procurement teams make informed decisions and act quickly if circumstances change.

Why supplier risk assessment matters in procurement

Modern procurement is about more than cost savings. Supply chain resilience, ethical sourcing, and operational continuity are now critical performance measures, and all depend on understanding and managing supplier risk.

Key benefits of a strong risk assessment process include:

- Protecting business continuity: By spotting vulnerabilities early, you can implement contingency plans before disruption occurs.

- Safeguarding reputation: Avoiding association with suppliers that breach regulations or ethical standards.

- Improving compliance: Ensuring suppliers meet legal, contractual and industry-specific requirements.

- Strengthening negotiation position: Informed risk insights can help you set realistic terms and service levels.

- Enhancing supplier performance: Targeted feedback and support can address weaknesses before they escalate.

Without structured risk assessment, procurement teams risk being blindsided by supplier failures, quality issues or non-compliance, often with significant financial and reputational costs.

Common challenges in supplier risk assessment

Even with the right intentions, many procurement teams struggle to implement risk assessment effectively. Common hurdles include:

- Fragmented data sources: Information scattered across spreadsheets, emails and multiple systems makes it difficult to get a complete view.

- Inconsistent evaluation criteria: Without standardised measures, assessments can be subjective and vary between evaluators.

- Lack of ongoing monitoring: Risks change over time, yet many organisations only assess suppliers at onboarding.

- Limited supplier transparency: Suppliers may be reluctant to share sensitive data or lack the systems to provide it.

- Resource constraints: Smaller teams may struggle to conduct thorough, regular assessments for every supplier.

The most effective procurement functions address these challenges by integrating risk assessment into everyday supplier management and using technology to automate and standardise the process.

Best practices for a strong supplier risk assessment process

A strong supplier risk assessment process doesn’t happen by chance. It’s the result of clear structure, consistent execution and the right tools. Here are some best practices you can use to create a solid, repeatable framework:

1. Define clear risk categories and criteria

Establish standard categories (financial, operational, compliance, ethical, geopolitical) and clear scoring criteria so all assessments are consistent and objective.

2. Use structured onboarding questionnaires

Gather detailed supplier information during onboarding using digital forms, covering financial stability, certifications, sustainability policies and operational capabilities.

3. Implement ongoing monitoring

Risk assessment shouldn’t stop after onboarding. Schedule regular reviews and track key indicators that could signal a change in risk profile.

4. Incorporate external data sources

Where possible, enrich internal data with third-party reports, credit checks and market intelligence to get a fuller picture of supplier stability.

5. Prioritise high-risk and strategic suppliers

Focus deeper assessment on suppliers that are critical to operations or represent higher inherent risk, while using lighter checks for low-risk categories.

6. Create clear escalation and action plans

Define thresholds for risk scores that trigger action, whether it’s additional audits, contractual changes or seeking alternative suppliers.

7. Use technology to centralise and automate

Leverage procurement platforms to store supplier data, automate reminders for reassessments and provide dashboards for real-time visibility.

How Atamis supports supplier risk assessment

Atamis provides procurement teams with integrated tools to manage supplier risk more efficiently and effectively.

Supplier Assurance Enhancer

Build and issue tailored questionnaires to assess risks in areas such as information security, social value, compliance and operational capacity. Automation ensures ongoing checks without repetitive data entry.

Risks and Issues Enhancer

Create, action, and monitor both risks and issues, recording likelihood and impact and developing management plans. Records can be shared with suppliers via the Supplier Portal to maintain transparency and collaboration.

Contract & Supplier App

Maintain a central database of supplier records with linked contracts, communications, and performance data, giving a single view of each supplier’s risk and performance profile.

SLA Monitoring

Document agreed service levels and track performance against them, identifying early warning signs of operational issues.

By integrating these features, Atamis helps procurement teams establish a continuous risk assessment cycle, from onboarding to contract renewal, helping them respond faster to changes and reduce overall risk exposure.

The future of supplier risk assessment in procurement

Supplier risk assessment is evolving rapidly, shaped by technology and global trends. Looking ahead, we can expect:

- AI-driven risk prediction: Using historical data and real-time inputs to forecast potential supplier issues before they occur.

- Greater integration of ESG metrics: Embedding sustainability and social responsibility deeper into risk scoring frameworks.

- Blockchain-enabled transparency: Improving traceability and authenticity of supplier-provided information.

- Dynamic risk modelling: Continuously updating risk profiles based on live market, geopolitical, and operational data.

Procurement teams that adopt these innovations will gain a competitive edge, ensuring their supply chains are both resilient and responsible.

Key takeaways

A strong supplier risk assessment process is essential to building a resilient, high-performing supply chain. By identifying and addressing risks early, procurement teams can protect operational continuity, safeguard reputation and enhance supplier performance.

The most effective approach combines clear, consistent evaluation criteria with ongoing monitoring and the right technology to automate and centralise the process. With solutions like Atamis, teams can turn risk assessment from a reactive task into a proactive, strategic capability that drives better procurement outcomes.

If you’re interested in learning how Atamis can help you embed a robust, continuous supplier risk assessment process, request a demo today.

Our Pipeline App empowers your team to plan ahead and forecast for upcoming procurement activities.

Our Pipeline App empowers your team to plan ahead and forecast for upcoming procurement activities.  The Tender App allows your team to visualise all sourcing activities within your Atamis platform, from issuing tenders to receiving bids.

The Tender App allows your team to visualise all sourcing activities within your Atamis platform, from issuing tenders to receiving bids. Our Contract & Supplier App puts your team in firm control of your key supplier relationships and provides a central repository for all contracts.

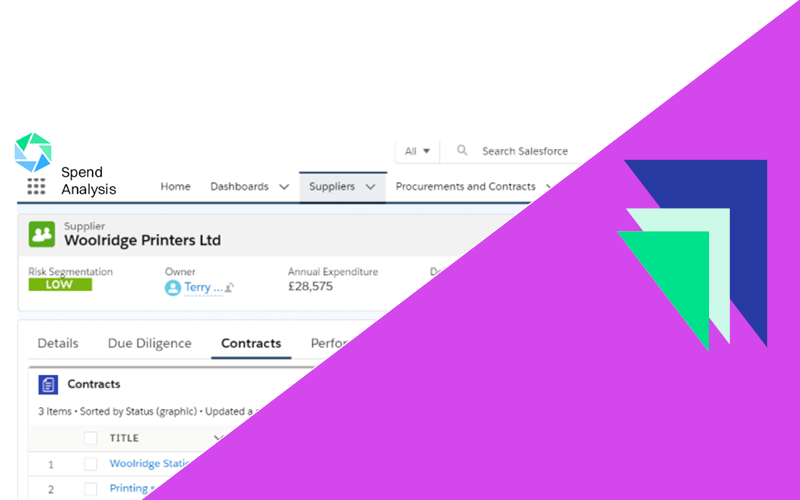

Our Contract & Supplier App puts your team in firm control of your key supplier relationships and provides a central repository for all contracts.  Our Enhancers ensure your solution is tailored to your needs. Pick and choose additional functionality that fits your requirements.

Our Enhancers ensure your solution is tailored to your needs. Pick and choose additional functionality that fits your requirements.