How the right SRM KPIs drive stronger supplier relationships

In today’s complex supply chains, suppliers aren’t just vendors, they’re strategic partners. The best procurement teams know that managing those relationships well can deliver significant value: cost efficiency, innovation, resilience and sustainability.

But effective supplier relationship management (SRM) doesn’t happen by accident. It requires structure, consistency and above all, visibility which means measuring the right things. That’s where SRM KPIs come in.

Tracking the right metrics gives procurement teams the insight to manage supplier performance proactively, mitigate risk early and identify opportunities for continuous improvement.

Yet, many organisations still struggle with what to measure and how to measure it.

So, let’s go back to basics and explore the most important KPIs you should be tracking in supplier relationship management, how they align with your strategic goals and how modern SRM software like Atamis helps bring it all together.

Why supplier KPIs matter

The old saying still holds true: “You can’t manage what you don’t measure.”

At Atamis we like to add “And you can’t measure what you can’t see”.

Without KPIs, supplier performance management becomes subjective. Decisions are based on opinions or isolated incidents rather than data and trends.

The right KPIs allow procurement to:

- Monitor supplier performance objectively and consistently.

- Identify underperformance before it impacts delivery.

- Recognise and reward high-performing suppliers.

- Support supplier development and improvement programmes.

- Align supplier activities with business priorities and values (e.g. sustainability or innovation).

In short, KPIs turn supplier management into a data-driven discipline, one that enhances collaboration, accountability and value creation.

How to choose the right supplier KPIs

Before diving into the specific metrics, it’s important to remember that there’s no universal set of KPIs that works for every organisation.

Your KPIs should:

- Align with your strategic objectives – e.g. cost efficiency, ESG goals, supply chain resilience or innovation.

- Be relevant to supplier type and category – performance measures for logistics providers will differ from those for marketing agencies.

- Be measurable and transparent – both parties should agree on how performance is defined, measured and reviewed.

- Encourage collaboration, not conflict – KPIs should drive improvement and partnership, not create a blame culture.

A good SRM software platform helps with this by allowing procurement teams to tailor KPIs, track them consistently and visualise trends over time.

The KPIs you should be tracking in supplier relationship management

Let’s break down the key metrics into logical categories, from performance and compliance to innovation and relationship strength.

1. Supplier performance KPIs

This is the foundation of SRM: measuring how well suppliers deliver against the agreed terms and expectations.

a) On-time delivery rate

- Measures the percentage of deliveries completed on or before the due date.

- A low on-time delivery rate can indicate logistical challenges, capacity issues or poor planning, all of which can impact your ability to meet your own commitments.

b) Quality performance / defect rate

- Tracks how often goods or services meet quality standards.

- High defect rates increase rework costs, waste and customer dissatisfaction, so it’s crucial to spot trends early.

c) Service level adherence

- Especially relevant for service-based contracts, this KPI measures how well suppliers meet agreed service levels (e.g. response times, uptime, resolution rates).

d) Cost adherence / variance

- Tracks whether suppliers deliver within agreed budget or pricing structures.

- Unexpected cost variances may highlight poor scoping, currency fluctuation or weak contract governance.

e) Lead time accuracy

- Measures whether suppliers deliver in line with agreed lead times, essential for managing inventory, production schedules or project timelines.

2. Risk and compliance KPIs

Supplier risk isn’t just about financial stability – it includes compliance, reputation, sustainability and even cybersecurity.

a) Compliance rate

- Tracks how many suppliers meet your compliance requirements (insurance, accreditations, certifications, policies, etc.).

- Non-compliance exposes your organisation to reputational and legal risk, so this KPI should be monitored continuously, not annually.

b) ESG compliance / sustainability rating

- More organisations are now tracking environmental and social performance alongside commercial metrics.

- This might include carbon footprint, waste reduction, diversity data or ethical labour practices.

c) Financial health score

- Assesses suppliers’ financial stability using credit ratings or payment history.

- Financial distress is often a leading indicator of supply disruption.

d) Risk incident frequency

- Measures how often supplier-related risks occur, from delivery failures to data breaches or regulatory issues.

e) Audit findings / corrective action closure rate

- Tracks how quickly suppliers respond to and close non-conformities raised during audits or assessments.

When integrated with the right SRM software, these risk metrics can trigger automated alerts or workflows when thresholds are breached, allowing procurement to act before issues escalate.

3. Relationship and collaboration KPIs

Strong supplier relationships are built on mutual trust, communication and collaboration. But how do you measure something that seems intangible?

a) Supplier satisfaction score

- Regularly survey your key suppliers to understand how they view your organisation as a customer.

- A low satisfaction score might indicate process friction, payment delays or poor communication, all of which can undermine performance.

b) Internal stakeholder satisfaction

- Similarly, measure how internal teams (e.g. operations, finance, legal) perceive supplier performance and collaboration.

c) Responsiveness / communication quality

- Tracks how quickly and effectively suppliers respond to queries, changes or issues.

- A responsive supplier is usually a reliable one.

d) Relationship health index

- Some organisations use a composite metric combining delivery, communication, and satisfaction scores to get a holistic view of supplier relationship health.

Modern SRM software platforms increasingly include built-in supplier surveys and collaboration portals to capture and analyse relationship data over time.

4. Innovation and value creation KPIs

Procurement is no longer just about cost savings, it’s about delivering innovation and strategic value through supplier partnerships.

a) Innovation contribution

- Measures the number or quality of innovative ideas, process improvements or new solutions proposed by suppliers.

b) Joint value creation

- Assesses the measurable benefits achieved through supplier-led initiatives, such as improved efficiency, reduced waste or product enhancements.

c) Continuous improvement participation

- Tracks how actively suppliers engage in improvement workshops, training or co-development projects.

d) Speed to implement innovations

- Measures how quickly supplier-driven innovations move from proposal to execution.

By using SRM software with tailored performance dashboards set up, procurement can track these contributions quantitatively and recognise suppliers who go above and beyond transactional performance.

5. Financial and commercial KPIs

While SRM is about more than savings, commercial efficiency is still crucial.

a) Cost savings / cost avoidance

- Quantifies the value created through renegotiations, efficiency improvements or reduced total cost of ownership.

b) Spend under management

- Measures the percentage of total spend covered by formal supplier relationships or contracts.

- Higher spend under management typically indicates greater control, compliance and strategic influence.

c) Payment terms compliance

- Tracks adherence to agreed payment terms, from both sides.

- Late payments can strain relationships and damage supplier trust, while early payments without discounts reduce working capital efficiency.

d) On-contract spend

- Shows how much spend actually flows through agreed contracts versus off-contract purchases, a critical measure of procurement influence and compliance.

The role of SRM software in tracking KPIs

Tracking KPIs manually through spreadsheets or static reports can quickly become unmanageable, especially for organisations with hundreds or thousands of suppliers.

That’s where SRM software like Atamis makes all the difference.

The right platform:

- Centralises supplier data so all performance, compliance and risk metrics are in one place.

- Automates performance tracking by integrating with ERP, contract and sourcing systems.

- Visualises KPIs in real time with dashboards and trend analysis.

- Enables collaboration through supplier portals where both sides can review and discuss performance.

- Supports continuous improvement with workflows for action plans, reviews and corrective measures.

In short, SRM software turns measurement into management. It gives procurement teams the tools to focus less on collecting data and more on driving improvement.

Making KPIs meaningful

Turning metrics into action

While KPIs are essential, they only add value when they’re:

- Agreed with suppliers so both sides understand expectations and targets.

- Reviewed regularly ideally quarterly or biannually, not just at contract renewal.

- Action-oriented metrics should lead to conversations and improvements, not just reports.

- A balanced focus on a mix of performance, risk, relationship and innovation measures to avoid tunnel vision.

Remember: SRM isn’t about policing suppliers, it’s about partnership. KPIs are the language of that partnership, helping both sides see what’s working and where to improve.

From measurement to better relationships

Strong supplier relationships don’t just happen, they’re built through consistent management, communication and measurement.

By tracking the right KPIs, procurement teams can move from firefighting to foresight, from transactional monitoring to strategic collaboration.

A more data-driven approach to SRM

The right SRM software partner helps make that shift possible, providing a single platform to manage, measure and strengthen supplier relationships across the full lifecycle.

So, if your supplier performance reviews still rely on spreadsheets and gut instinct, it might be time to take a more data-driven approach.

Because when you measure what matters, you don’t just manage suppliers better, you unlock their full potential to help your organisation succeed.

Ready to take a more data-driven approach to SRM?

If your supplier performance reviews still rely on spreadsheets and gut instinct, it may be time to rethink how you manage and measure supplier relationships.

Discover how Atamis helps organisations define, track and act on the SRM KPIs that matter, and turn supplier data into long-term value.

Ready to bring your supplier KPIs to the fore?

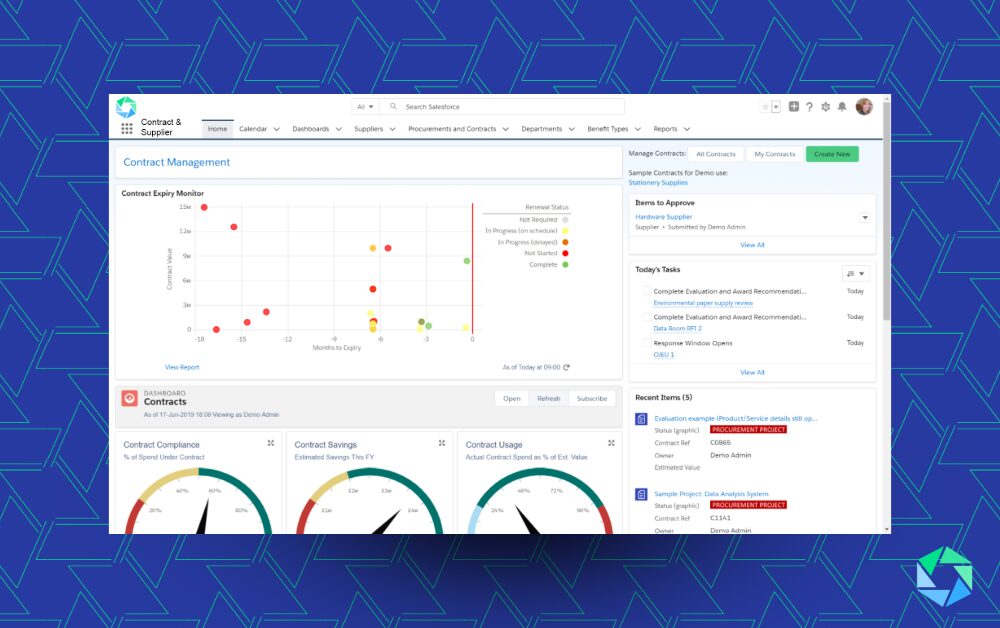

Atamis’ supplier relationship management tools give procurement teams complete visibility of supplier performance, risk and value, with configurable KPIs, bespoke dashboards and real-time analytics that make managing suppliers simpler, smarter and more strategic.

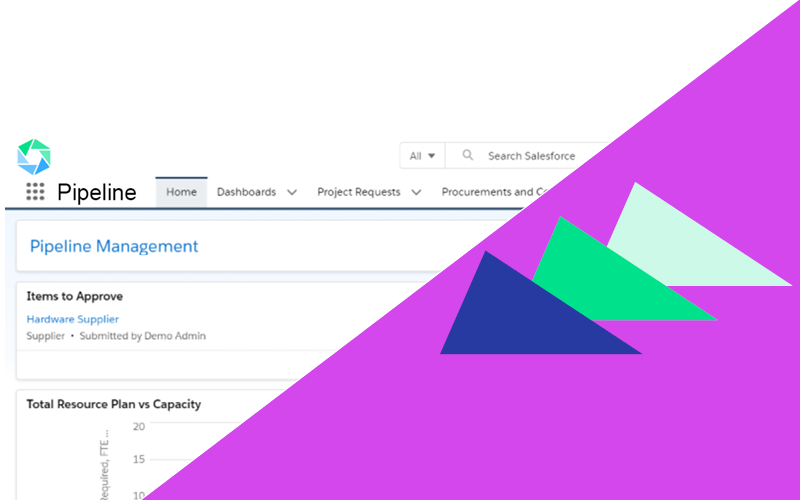

Our Pipeline App empowers your team to plan ahead and forecast for upcoming procurement activities.

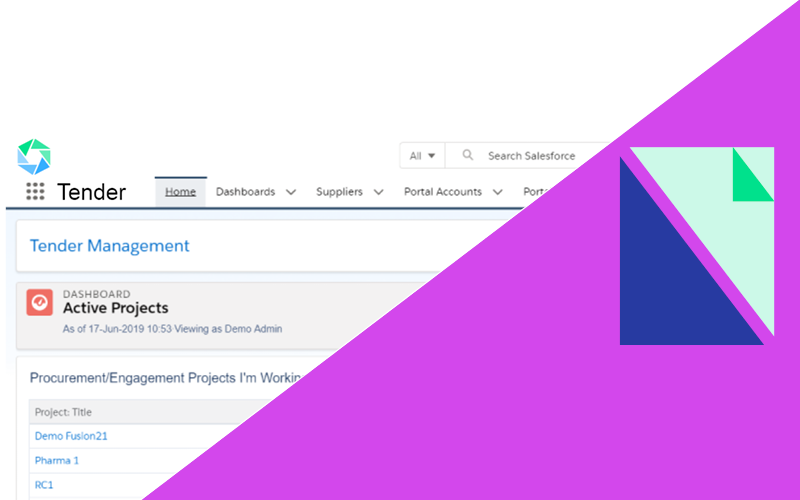

Our Pipeline App empowers your team to plan ahead and forecast for upcoming procurement activities.  The Tender App allows your team to visualise all sourcing activities within your Atamis platform, from issuing tenders to receiving bids.

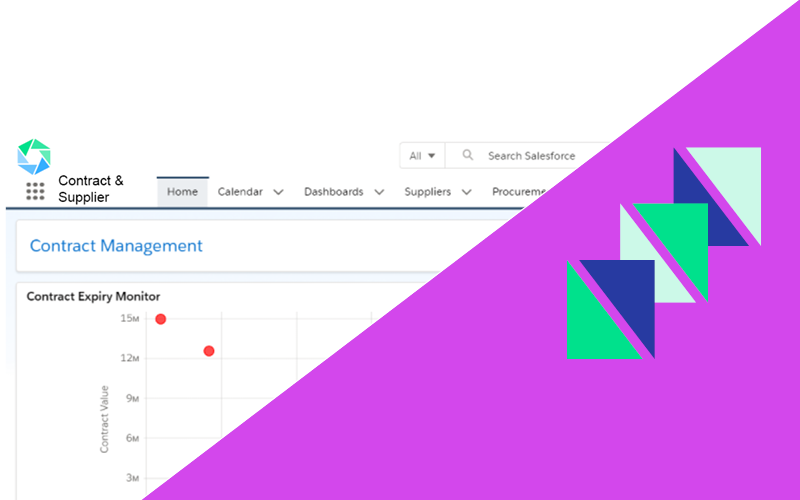

The Tender App allows your team to visualise all sourcing activities within your Atamis platform, from issuing tenders to receiving bids. Our Contract & Supplier App puts your team in firm control of your key supplier relationships and provides a central repository for all contracts.

Our Contract & Supplier App puts your team in firm control of your key supplier relationships and provides a central repository for all contracts.  Our Enhancers ensure your solution is tailored to your needs. Pick and choose additional functionality that fits your requirements.

Our Enhancers ensure your solution is tailored to your needs. Pick and choose additional functionality that fits your requirements.